Thank you for Subscribing to Construction Business Review Weekly Brief

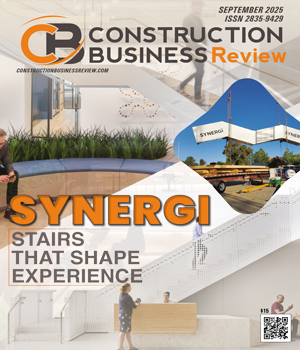

Stairs shape how people move through a space, how they pause, and what they notice. Whether they stand out or disappear into the architecture, they play a crucial role in how a space feels. However, making that kind of impact requires more than design intent. It takes a team that knows how to carry that vision from paper to reality without missing a step. That is where Synergi comes in. While many others focus on metal fabrication or cover only a specific region, Synergi offers comprehensive stair solutions and serves clients nationwide. “Our process covers everything. We design, engineer, fabricate, and install every stair element, whether it is glass, metal, wood, or structural steel,” says Walter Bowie, vice president, client relations. That full-scope capability is essential, but what truly makes the most significant difference is Synergi’s timing. The team often gets involved early, before a design is finalized. As soon as a design concept or schematic begins to take shape, Synergi jumps into a collaborative format. This means sitting at the table with architects, engineers, contractors, and clients, working through every challenge together. Weekly or biweekly meetings are the norm, and it is during these sessions that design intent merges with constructability and gets translated into engineered solutions. Input is gathered, drawings evolve, and the stair begins to take its true shape. Tailored Solutions for Every Vision Of course, no two clients come with the same needs. Some are racing against tight deadlines and need a stair delivered fast. Others want something visually striking but have to keep the budget in check. Then, there are those projects where the design team arrives fully committed to a concept they have already embraced. The materials have been chosen, the shape is admired, and the team is fully invested. Then, the engineering review begins and reveals that the structure needs to be bulkier or that the finish materials add too much weight. That is when Synergi’s experience becomes essential. One particular project at a large higher education life sciences institution brought that scenario into sharp focus. The design called for a sweeping two-level spiral stair set in a grand atrium. At first glance, everything looked perfect. But when Synergi’s engineers took a closer look, they discovered that the stair would weigh nearly 50,000 pounds. Between the exposed steel structure and tall guardrails, the load was enormous. The building’s existing floor slab was not designed to handle it.

Top Commercial Plumbing Service in Florida 2025

From the modest neighborhoods of post-war Buffalo to the commanding skyline of Florida’s Gulf Coast, Ackerman Plumbing has stayed true to its roots while becoming one of the state’s leading commercial plumbing contractors. It provides full-service solutions for building managers and construction professionals, including new construction, maintenance, and emergency repairs. Ackerman Plumbing’s story began in 1946 when Ray Ackerman and Charlie Huebsch, two of the most trusted employees at Weinheimer Plumbing, received their employer’s blessing to start their firm on the condition they would not compete. That gesture of trust laid the foundation for what would become a legacy business, built on technical expertise and long-term relationships and values that endure. The early years were defined by agility and foresight. With the post-war housing boom in full swing, Ackerman Plumbing quickly distinguished itself by embracing prefabrication. The company assembled plumbing systems off-site by standardizing layouts across a handful of home designs, reducing time, waste, and on-site labor. That strategic approach helped meet massive housing demands while foreshadowing its commitment to efficiency and innovation, principles that remain central to its operations today. Now headquartered in Florida and led by third-generation master plumber and president Eric Ackerman, the company has transitioned from residential builds to complex commercial infrastructure. Its client roster includes some of the most recognizable names in construction, and its projects span sectors like multifamily housing, healthcare, education, and aviation. “We’re not just growing for growth’s sake. We’re building something lasting for our clients, our communities, and the people who work here,” says Eric. Heritage Meets Innovation in Florida’s Fastest-Growing Plumbing Contractor Ackerman’s long-standing reputation is anchored in its ability to deliver highly specialized, large-scale projects quickly and precisely. A prime example is 400 Central, the tallest residential building on Florida’s West Coast. Spanning 46 stories, the project involved years of early collaboration and planning. Eric and his team worked closely with Suffolk Construction during the budgeting phase, two years before construction began, highlighting the company’s commitment to partnership and performance. The build included over eight miles of water piping and 10,000 feet of sanitary lines.

Top ADU Design-Build Firm in California 2025

Creating extra living space for a source of extra income or to accommodate extended family sounds like a smart move—until you’re knee-deep in permits, floor plans and contractor delays. That’s where Urbatect Development steps in. They don’t just build accessory dwelling units (ADU); they streamline the entire process from the first sketch to the final walkthrough. Urbatect’s design-build workflow model makes the difference. By aligning estimators, designers and builders under one roof, the firm creates a cohesive delivery system that serves as a single team with full control over timelines, budgets and execution. For property owners, that means sitting back and trusting a partner who brings the right expertise and intent to deliver high-quality results with clear communication, without the friction and liability of coordinating multiple teams. That accountability is strengthened by experience. Since California passed its ADU laws in 2019, Urbatect has completed hundreds of units across the state. From the Bay Area to Orange and San Diego counties, the team knows the ins and outs of local codes and approval processes. It can clear red tape faster and get projects off the ground sooner. “Every ADU we build is about making the most of what you already own,” says Eric Martinez, owner. “We are not just adding square footage; we are turning your property into a smarter, more flexible asset.” A Ground-Level Team with a Big-Picture Mindset Every great build starts with better thinking. From the first conversation, the Urbatect team brings a proactive, problem-solving mindset. Sales specialists, for instance, do far more than capture wish lists. They dig deeper by combining design sensibility with real-world construction know-how. Drawing from firsthand experience managing job sites and schedules, they bring both design awareness and field-tested insight to the table. That practical lens allows them to ask the right questions early, identify constraints others might overlook and steer the conversation toward buildable solutions. By aligning scope, budget and timeline before a contract is signed, they lay the groundwork for smoother approvals, fewer surprises and stronger financial control.

CXO INSIGHTS

Construction services with a Focus on Value and Technical Proficiency

Jake Tucker, Silicon Valley Special Projects Lead, Turner Construction

The Top Three Benefits of Modular Construction

Jake Snyder, Director of Preconstruction, Hoar Construction

Transforming Concrete Pouring with Innovative Formwork Solutions

Tadas Ciuckys, Director of Engineering, Doka USA

Revolutionizing Sustainable Building with Industrialized Construction

Walter Terry, Vice President, Rudolph and Sletten

Mass Timber a Sustainable Approach to Modern Construction

Pete Kobelt, Director, Mass Timber Solutions, STO Building Group

IN FOCUS

Precision and Expression: Trends in Architectural Stair Services

The architectural stair services industry blends aesthetics and functionality, focusing on innovative, sustainable designs that prioritize craftsmanship, technology, and personalization in modern construction.

Concrete Cutting as a Strategic Contributor to Construction Success

The concrete cutting industry has evolved into a precision-driven discipline, essential for the successful execution of modern construction's complex projects, emphasizing specialized expertise and advanced technology.

EDITORIAL

Design Build Dynamics Driving Efficiency and Innovation in Construction

Within this evolving landscape, California stands out as a hotspot for advanced construction practices, particularly in the accessory dwelling unit (ADU) market. Leading design-build firms in the state leverage integrated workflows to navigate stringent regulatory environments and meet housing shortages. Complementary services like commercial plumbing, precise concrete cutting, and architectural stair design are integral to these projects, ensuring compliance, structural integrity, and aesthetic sophistication. Together, these capabilities create a comprehensive ecosystem that supports California’s ambitious construction goals and sets new standards for quality and efficiency.

This edition of Construction Business Review explores how integrated design-build models, specialized trades, and advanced construction techniques are transforming the building landscape. From the pivotal role of ADU firms to the impact of commercial plumbing, concrete cutting, and architectural stair services, it examines the key elements driving efficient and innovative project delivery.

It features Urbatect Development, a leading design-build firm that amplifies ADU projects by uniting estimators, designers, architects, and builders to maintain full control over timelines, budgets, and execution from concept through completion. It also highlights Ackerman Plumbing’s expertise in commercial plumbing and large infrastructure across multiple sectors, SCANTEK GPR’s 24/7 concrete services with advanced detection technology, and Synergi’s award-winning team delivering turnkey architectural stairs that blend function and style.

We hope this edition offers valuable insights into the innovative approaches and collaborative expertise shaping the construction industry today, inspiring professionals to embrace integrated solutions for greater efficiency and quality.